- 2/453,Kasipillampalayam

Perundurai - 638 056. - +91 98650 48581

srisakthiengineering1@gmail.com

Steam Jet-Liquid Jet Ejector Combination Systems are ideal to handle small quantities of non-condensable gases and large quantities of condensable vapors on intermittent or batch processes. Low level mounted and energy conserving with effective scrubbing of outlet gases, offers the advantage over other systems in producing vacuum and simultaneously scrubbing entrained gases before discharging to the atmosphere, making it an ideal selection for contaminated and/or corrosive applications.

They are available in multi-element form as a central vacuum source on multi-purpose process applications.

They are generally used to create vacuum upto 759 mm of Hg in medium size process vessels.

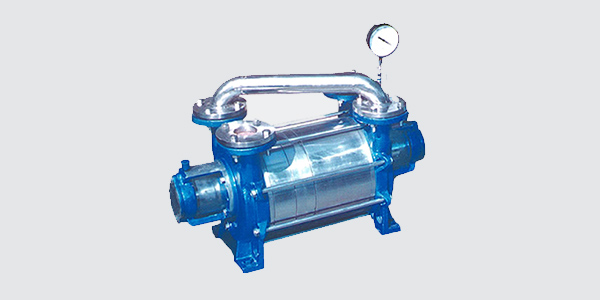

Liquid Ring Vacuum Pumps are specially designed to operate using water, solvent or any other clear liquid and generate vacuum corresponding to the vapor pressure of the liquid. They are very useful for applications when expensive process fluid is to be recovered. They are most suitable for low non-condensable and high condensable loads in applications like distillation and evaporation.

xternal heat exchanger can be provided to maintain liquid temperature in accordance with vacuum requirement. For higher vacuum, liquid jet ejector can be utilized along with a steam jet ejector combination system. The whole system can be supplied as a pre-assembled skid mounted unit for quick installation.

The ejectors which are distinguished from other types of compressors as having no moving parts, work on the ejector-venturi principle of converting the pressure energy of a motivation fluid to velocity energy in order and mixture of gas and steam enters the venturi diffuser where its velocity energy is converted into

pressure energy, sufficient to discharge against predetermined back pressure.

Product may be passed through the evaporator in forward, back or mixed flow configuration.

Thermocompressors are finding increased applications in paper, food, pharmaceutical, chemical and other process industries in steam dryers, vacuum dryers, evaporators, deodorizers, etc.